Manufacturing Process

-

- Powder Preparation

- The base materials, binders and solvents are mixed and then prepared as well flowing granules with a spray drier.

-

- Molding

- Pressure is applied to combine the prepared granules to the required size and prepare a block with the hardness of chalk.

-

- Green Machining

- Since ceramics are difficult to machine after sintering, green machining is performed before sintering to get the product close to its final shape.

-

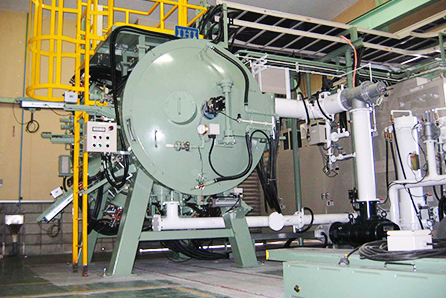

- Sintering

- The product is sintered in the correct atmosphere and temperature for the material. After sintering the ceramics, they shrink to about 80% of the size before sintering.

-

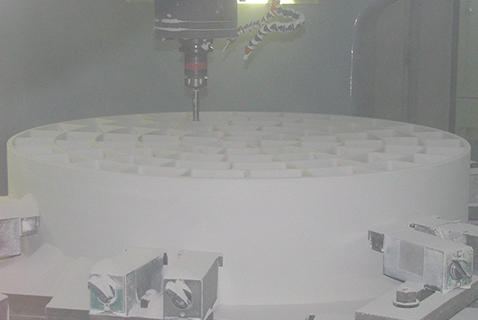

- Final machining

- Surface grinders, machining centers and other machine tools are used to machine the product until it meets precision requirements.

-

Example machining equipment:

- Surface grinder

- Machining center

- Cylindrical grinder

- Precision lapping machine

- Large lapping machine

-

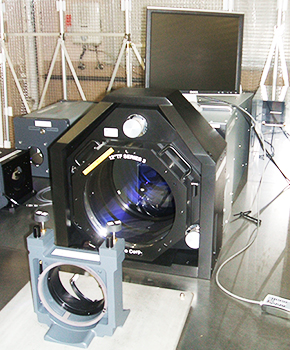

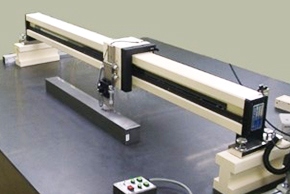

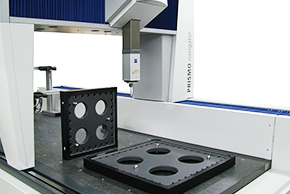

- Inspection

- Various inspection devices are used to check if the product meets dimensional and other specifications before shipment.

-

Example inspection devices

- 3D CMM

- Laser interferometer

- Ultrasonic test equipment

- Straightness measurement machine