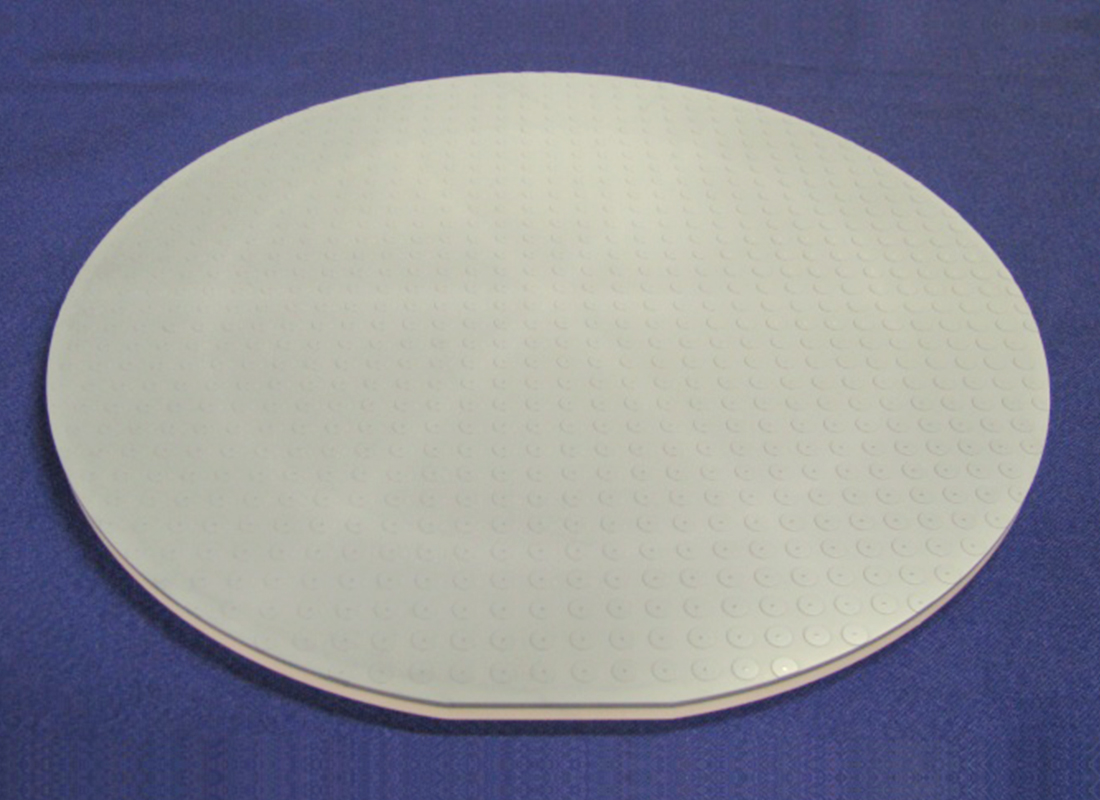

Electrostatic Chuck

In semiconductor production vacuum processes, electrostatic chucks are used to secure, carry and correct components such as wafers.

Our company’s Johnsen-Rahbek electrostatic chucks are highly regarded for our original material technology and machining technology.

Features

- Excellent chucking/de-chucking response

-

By optimizing material structure, the chuck demonstrates extremely excellent chucking/de-chucking response.

This contributes to vast improvements in throughput. - Excellent flatness

-

Our original polishing technology gives a highly precise flatness across whole surfaces.

Additionally, since we can achieve a great surface roughness, it is possible to reduce the particle and to increase the cuncking force. - High durability

- Since dielectric, internal electrode and insulator are sintered as a single unit, it features excellent stability over extended times compared to electrostatic chucks bonded with an adhesive.

Material Properties

| Materials | TiO2-doped Al2O3 Ceramic | |

|---|---|---|

| Bulk Density | g/cm3 | 3.98 |

| Young's Modulus | GPa | 400 |

| Poisson's Ratio | - | 0.24 |

| Fracture Toughness | MPa・m1/2 | 4.6 |

| Hardness | 98N, GPa | 14 |

| Dielectric Constant (1MHz) | - | 10.7 |

* The data indicated herein is representative values and not guaranteed values.

Product data (reference value)

- ・Applied Voltage:+300V / -300V

- ・Chucking/De-chucking response time: < 3 seconds

- ・Chucking Force: 706 N (φ 300 mm, 0.75% pin surface)

* The data indicated herein is representative values and not guaranteed values.