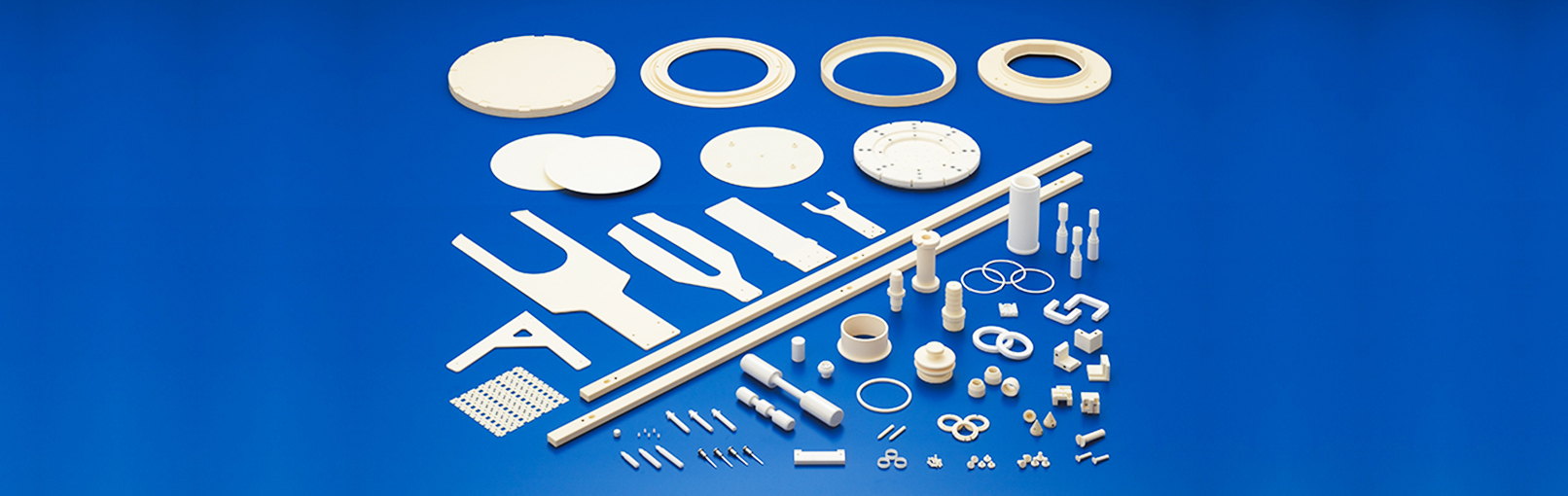

Oxide Engineering Ceramics

Engineering ceramics are a kind of fine ceramics characterized by thermal resistance, corrosion resistance, hardness and other properties that are useful in construction materials.

Compared to general metallic materials, it is lighter and has high stiffness with excellent electrical resistance in a variety of environments.

Our oxide based engineering ceramics are used in a wide assortment of fields in components from industrial to semiconductors and electronic devices.

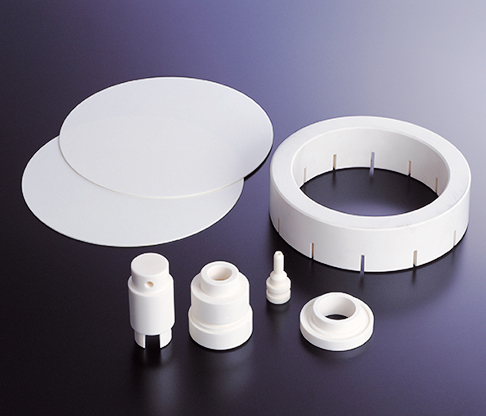

Alumina

This material is the most widely used fine ceramics as a general-purpose high-purity material with a balance of thermal resistance, electrical insulation and wear resistance. It has corrosion resistance, mechanical strength and high hardness.

This material has a wide array of applications including high temperature furnace components use its thermal resistance, insulators that use its electrical resistance, components for industrial devices that use its mechanical strength, semiconductor production devices, high precision large materials for use in LCD production devices and so on.

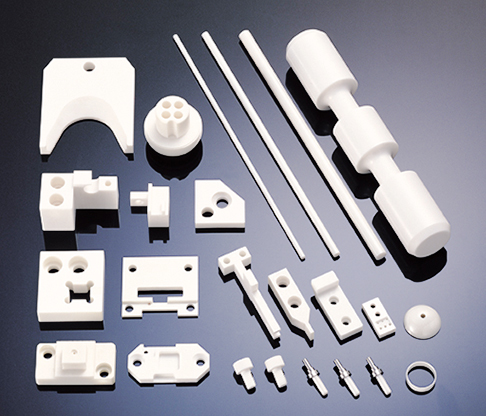

Zirconia

This material features the highest toughness and strength at room temperature of all fine ceramics.

This mechanical strength and excellent wear resistance are useful in sliding materials or wear resisting components such as guide rollers.

The high level of toughness is also used in various kinds of blades such as scissors or cutters.

A black type (MZR-K) is also available for wear resistant components for image recognition.

L-TEX

With low thermal expansion, this material performs advantageously in thermal resistance and thermal shock strength.

Since it also offers mechanical strength, L-TEX can be used in high temperature environments while under load.

Used in parts for high temperature applications such as in bobbin heaters and electrically resistant components used in rapidly heating or cooling environments.

Material characteristics

| Name | ALUMINA | ZIRCONIA | L-TEX | |||

|---|---|---|---|---|---|---|

| Code | A115 | A118 (former MA995) |

AB117 | MZR | L-TEX | |

| Composition | Al2O3 99.5% | Al2O3 99.7% | Al2O3 | ZrO2 | - | |

| Color | ivory | ivory | black | white | light grey | |

| Bulk Density | g/cm3 | 3.85 | 3.90 | 3.90 | 6.00 | 2.70 |

| Water Adsorption Ratio | % | 0 | 0 | 0 | 0 | 0 |

| Flexural Strength | MPa | 330 | 340 | 440 | 1100 | 150 |

| Compressive Strength | MPa | - | 2900 | - | 3000 | - |

| Young's Modulus | GPa | 370 | 350 | 390 | 210 | - |

| Poisson's Ratio | - | 0.24 | 0.23 | 0.23 | 0.32 | - |

| Hardness | GPa | 15.0 | 15 | 15.2 | 13 | - |

| Fracture Toughness | MPa・m1/2 | 4.2 | 4.7 | 3.4 | 5.5 | - |

| Electrical Resistivity [RT] | Ω・cm | >1015 | >1015 | - | - | >1013 |

| Dielectric Constant [1MHz] | - | 10 | 10 | - | - | 6.5 |

| Dielectric Loss (tanδ) [1MHz] | - | 0.006 | 0.005 | - | - | - |

| Dielectric Strength | kV/mm | - | 10 | - | - | 10 |

| Thermal Expansion Coefficient [RT] | ×10-6/℃ | 5.4 | - | 5.3 | - | - |

| Thermal Expansion Coefficient [RT-400℃] | ×10-6/℃ | - | 7 | - | 10 | 3.1 |

| Thermal Expansion Coefficient [RT-800℃] | ×10-6/℃ | - | 7.9 | - | 10.3 | 4.0 |

| Thermal Conductivity [RT] | W/(m・K) | 32 | 30 | 24 | 3 | 3 |

| Specific Heat [RT] | J/(g・K) | 0.78 | 0.8 | 0.73 | 0.5 | - |

| Thermal Shock Resistance ⊿T | ℃ | - | 200 | - | 250 | 350 |

* The data indicated herein is representative values and not guaranteed values.