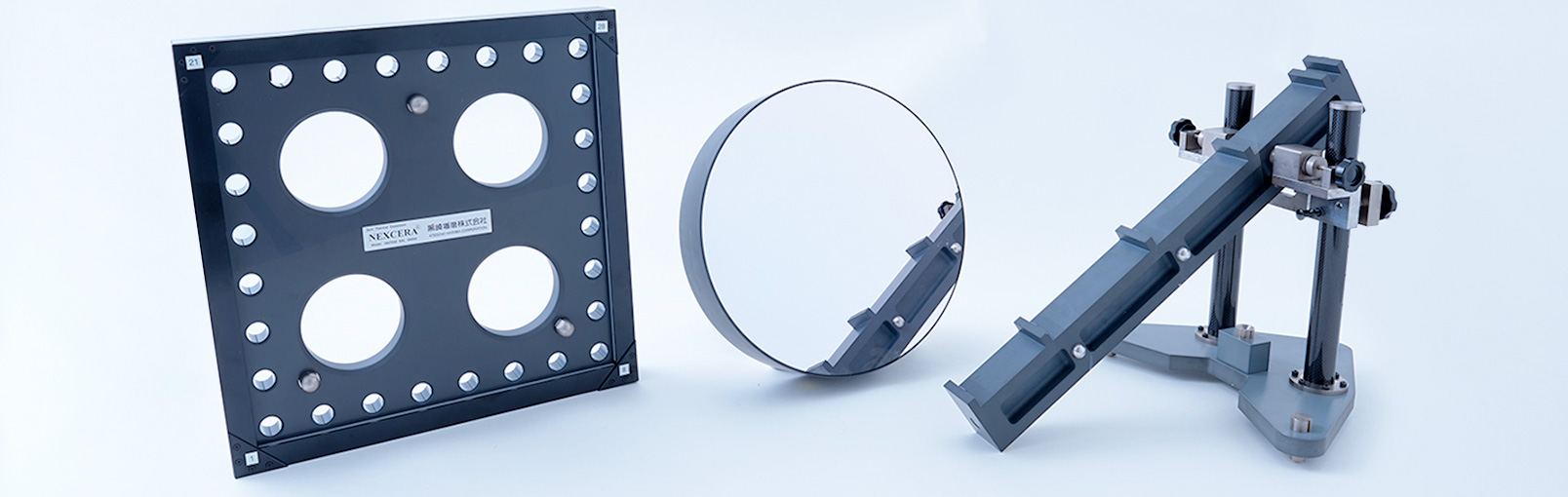

NEXCERA™ ultra low thermal expansion ceramics

NEXCERA™ is an ultra-low thermal expansion ceramic with a cordierite base (2MgO-2Al2O3-5SiO2). It features zero expansion near room temperature and is stronger and more durable than low thermal expansion glass. It is able to be used in shapes more complex than could be achieved before.

Features

- Zero thermal expansion coefficient

- Near zero expansion at temperatures close to room temperature.

- High aging and thermal stability

- Dimensional changes over time are extremely low and thermal expansion/dimensional reproduction related to changes in temperature are very good.

- Light weight/high stiffness

- Compared with general low thermal expansion glass, NEXCERA™ has about 50% more stiffness.

- Precision mirror machining possible

- As a pore-less material it can be given a mirror finish by lapping and polishing.

- Near net shape sintering technology

- Able to be sintered with near net shapes by machining before sintering enabling manufacturing of complex shapes at low cost.

Thermal expansion behavior

NEXCERA™ Applications

Material characteristics

| Code | N113B | N117B | N118C | N119C | CD107 | |

|---|---|---|---|---|---|---|

| Color | black | black | blue-grey | light blue-grey |

blue-grey | |

| Bulk Density | g/cm3 | 2.5 | 2.55 | 2.58 | 2.5 | 2.57 |

| Flexural Strength | MPa | 210 | 230 | 220 | 166 | 230 |

| Young's Modulus | GPa | 130 | 140 | 140 | 130 | 143 |

| Specific Stiffness | GPa/(g/cm3) | 52 | 55 | 54 | 52 | 55 |

| Fracture Toughness | MPa・m1/2 | 1.2 | 1.2 | 1.4 | 1.3 | 1.4 |

| Hardness | GPa | 8.0 | 8.1 | 8.1 | 8.0 | - |

| Thermal Expansion Coefficient | X10-6/℃ 23℃ | < 0.03 | < 0.03 | < 0.05 | < 0.05 |

< 0.03 (at 22℃) |

| Thermal Conductivity | W/mK | 3.7 | 4.2 | 4.5 | 4.3 | 4.7 |

| Dielectric Constant | (1MHz) | 4.7 | 6.0 | 4.7 | 4.4 | 4.6 |

* The data indicated herein is representative values and not guaranteed values.