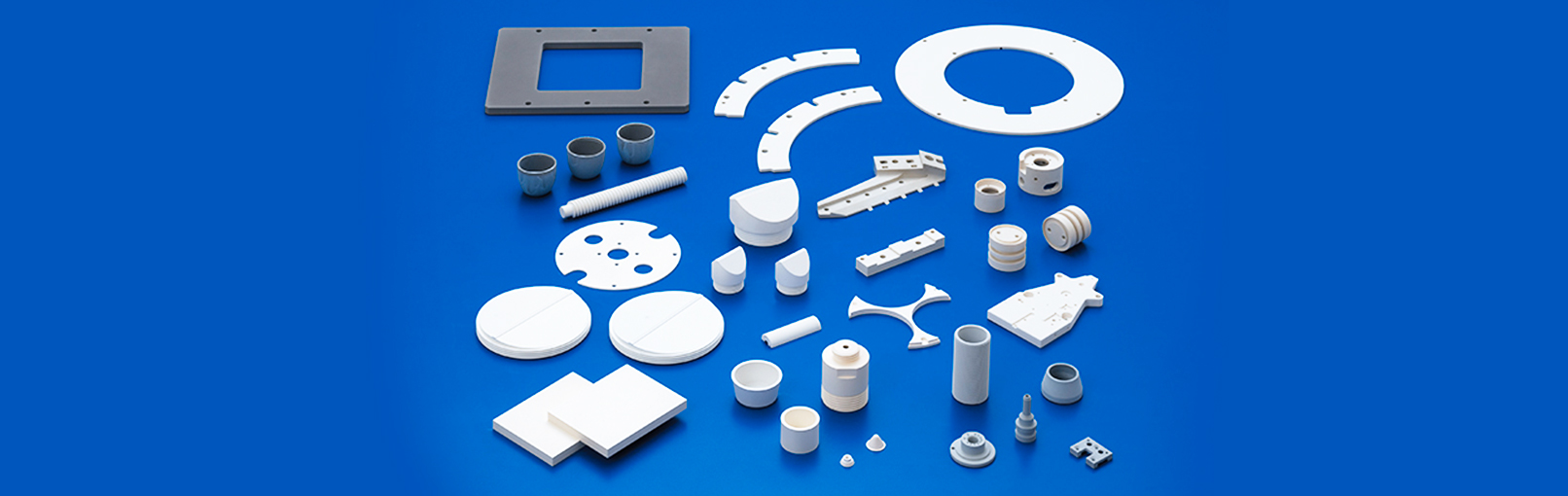

BN type, AlN type, Porous Machinable Ceramics

We offer a wide assortment of machinable ceramics including BN, AlN type, and porous machinable ceramics.

Each materials has unique characteristics in addition to excellent machinability.

BN (Boron nitride) type

BN HC / BN N-1

Hexagonal Boron Nitride has excellent thermal resistance properties in inert atmosphere.

Excellent thermal shock strength and insulation properties at high temperature.

Inactive against melted metal and molten glass.

SBN

Composite materials of BN and silicon nitride.

Better mechanical strength and wear resistant properties than BN.

AlN (Aluminum nitride) type

SHAPAL™ Hi Msoft

Composite materials of Aluminum nitride and BN.

High thermal conductivity and mechanical strength.

Porous

MACHINAX

Porous machinable ceramics.

ALMATITE

Very low thermal expansion coefficient and high thermal shock resistance properties.

Inactive against melted metal.

Material characteristics

| Classification | BN (Boron nitride) type | AlN (Aluminum nitride) type | Porous | ||||

|---|---|---|---|---|---|---|---|

| Code | BN HC | BN N-1 | SBN | SHAPAL™ Hi Msoft | MACHINAX | ALMATITE | |

| Composition | Hexagonal BN | Hexagonal BN | BN-Si3N4 | AlN-BN | CaSiO3 | Al2TiO3 | |

| Color | white | white | light grey | light grey | white | grey | |

| Bulk Density | g/cm3 | 2.00 | 1.80 | 2.50 | 2.88 | 2.10 | 3.30 |

| Water Adsorption Ratio | % | - | - | - | 0 | 10 | 1.8 |

| Flexural Strength | MPa | 35 | 30 | 270 | 300 | 50 | 10 |

| Compressive Strength | MPa | 50 | 20 | - | 100 | 250 | 150 |

| Young's Modulus | GPa | 18 | 15 | 55 | 177 | 52 | - |

| Poisson's Ratio | - | - | - | - | 0.31 | - | - |

| Hardness | GPa | 1.3 | 0.8 | 5.5 | 3.7 | 2.6 | 1.5 |

| Fracture Toughness | MPa・m1/2 | - | - | - | - | - | - |

| Electrical Resistivity (RT) | Ω・cm | >1015 | >1015 | >1014 | >1015 | >109 | >1012 |

| Dielectric Constant [1MHz] | - | 4 | 4.5 | 6.3 | 6.8 | 5 | 13 |

| Dielectric Loss (tanδ)[1MHz] | - | 0.0008 | 0.0009 | 0.0053 | 0.001 | 0.012 | 0.007 |

| Dielectric Strength | kV/mm | 20 | 19 | - | 65 | 10 | 7 |

| Max. Useable Temperature | ℃ | 1800※1 | 2200※1 | 1700※1 | 1900※1 | 900※2 | 900※2 |

| Thermal Expansion Coefficient (RT) | ×10-6/℃ | - | - | - | - | - | - |

| Thermal Expansion Coefficient (RT-400℃) | ×10-6/℃ | - | - | - | 4.8 | 7.0 | -2.1 |

| Thermal Expansion Coefficient (RT-800℃) | ×10-6/℃ | -0.25※3 | -1.4※3 | 2.6※3 | 5.0 | 7.5 | -0.9 |

| Thermal Conductivity (RT) | W/(m・K) | 36 | 63 | 47 | 92 | 1.6 | 1.5 |

| Specific Heat (RT) | J/(g・K) | - | - | - | - | 0.8 | 0.8 |

| Thermal Shock Resistance ⊿T | ℃ | - | - | - | 400 | 250 | 900 |

| Remarks | Denka Co., Ltd. | Tokuyama Corp. | |||||

- ※1 non-oxidative atmosphere

- ※2 oxidative atmosphere/no visual change in appearance

- ※3 measured at [RT-1000℃]

* The data indicated herein is representative values and not guaranteed values.