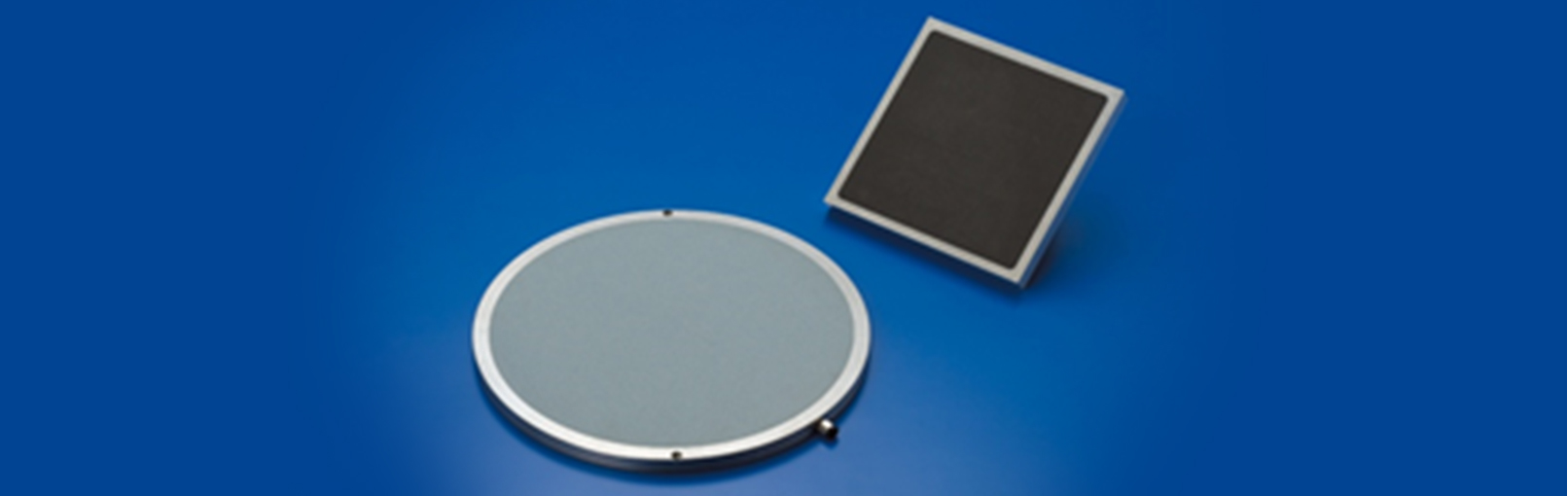

Vacuum Chuck

Our vacuum chuck takes advantage of the properties of porous ceramics.

Porous ceramics are formed by continuous holes connecting from the inside to the surface like a sponge.

There are many names for this technology such as vacuum chucking plate or chucking plate. The chucking surface uses vacuum to fix the affixed object with atmospheric pressure. This operates with the same principle as a suction pad.

Conventional solutions use channels for air such as grooves or holes formed by machining. This results in issues such as deformation of films and thin products getting sucked into the grooves or holes. Our porous ceramics have micron-scale holes across the whole surface enabling even adhesion without deformation of the fixed object.

We handle production of the vacuum chuck from materials to machining enabling us to support a wide range of options.

Contact us for details.

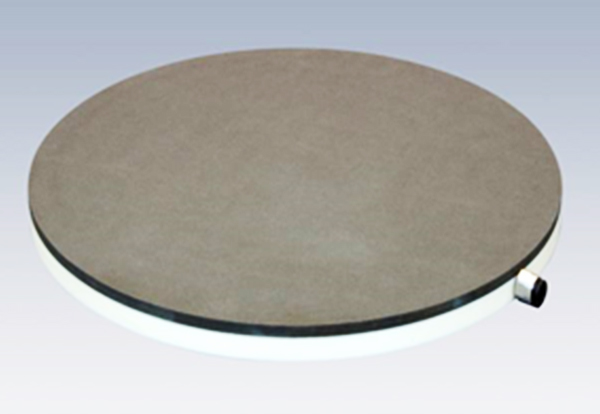

Porous chucking plate

Using the characteristics of porous ceramics enables objects (films, boards, wafers, etc.) to be evenly fixed without inconsistencies in chucking force. This enables suction in atmosphere of both magnetic and non-magnetic parts.

It is appropriate for chucking thin components such as thin semiconductor devices, 3D memory boards, membranes/films, flip chip bonder chucking stages, and more.

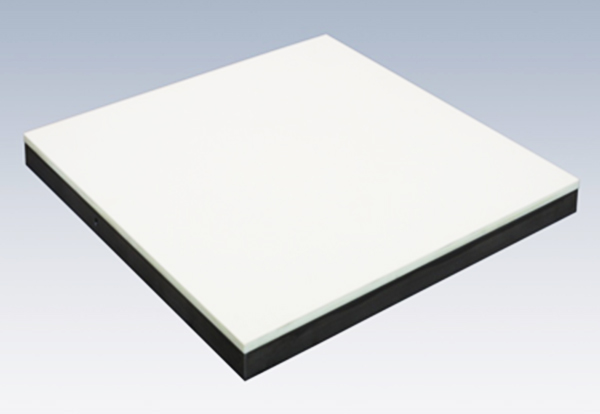

Partial chucking plate: AH chucking plate

Chucking plates are made using special material porous ceramics (AH) enabling partial chucking.

It is possible to fix workpieces with different sizes (for example 8” and 12”) on a single plate.

Normal porous chucking plates are unable to fix objects unless the entire surface is covered since vacuum will leak. AH chucking plates use materials with controlled pore diameter and ratios to eliminate leaks on free surfaces enabling fixing of objects with partial chucking by maintaining vacuum state.

Some of the many applications include dry machining chucking stages and fixing stages for inspection that support varied shapes.

Product lineup: Technology overview

Lineup

| product name | av. pore diameter (μm) | porosity (%) |

|---|---|---|

| MP580 | 580 | 45~50 |

| MP230 | 230 | 45~50 |

| MP130 | 130 | 45~50 |

| MP100 | 100 | 45~50 |

| MP060 | 60 | 45~50 |

| MP040 | 40 | 45~50 |

| Conductivity | 25 | 15~18 |

| AH | 2 | 30~35 |

- ・Our standard porous products come in 100μm and 60μm but we can support other pore diameters on request.

- ・Standard flatness: 5μm

- Exact numbers depend on sizes, shapes and used temperatures. Contact us for details.

※The data indicated herein is representative values and not guaranteed values.

- ・We also support large products, square pads and many other shapes.

- ・We can provide products supporting applications and requests such as heater internal components, use of conductive materials, black color base (for image recognition) and more.

High accuracy porous chucking plate

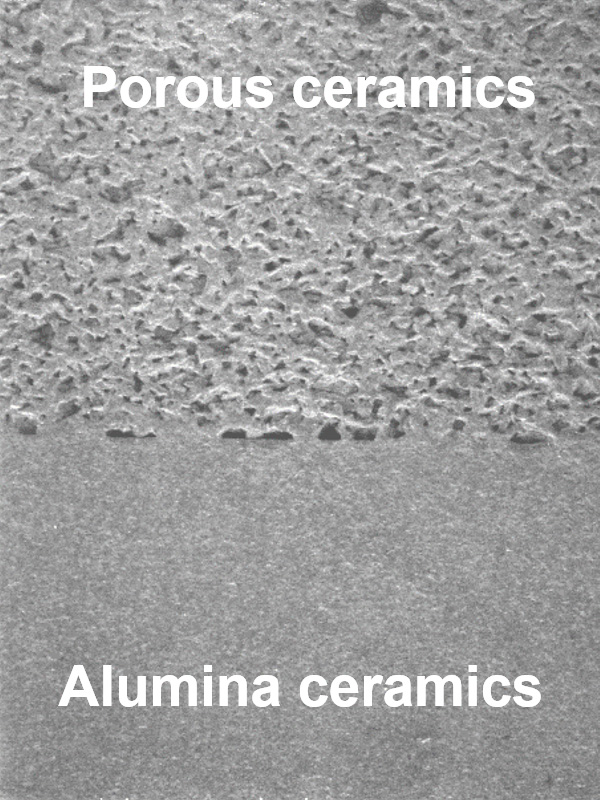

Photo of SEM bonding surface

- ・Standard products that affix to metallic (SUS or aluminum) base parts and porous ceramics differ. Using light (density 3.9 g/cm3) and highly stiffness alumina ceramics for base parts enables improved dimensional accuracies for chucking plate.

- ・The 300 mm diameter size enables support for surface parallelism of 3μm or less.

- ・Compared to vacuum chucks with metallic base, this product features greatly improved stability of adhesion precision which is affected by aging and thermal change.

- ・Using special bonding solves issues related to gaps that occur at the bonding boundary surface. This prevents drooping from chucking and pressure.